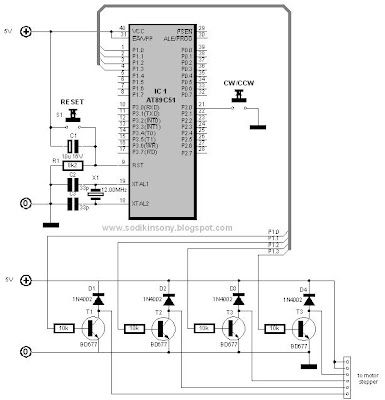

CW-CCW-RUN-STOP controls

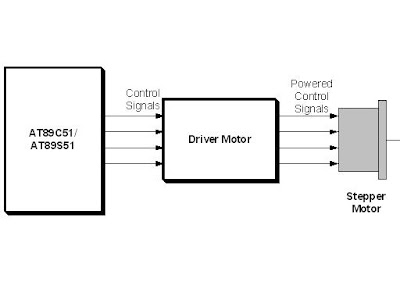

By Sony Sodikin http://www.sodikinsony.blogspot.com/ To run the motor in clockwise rotation, first step is press the CW switch and then press the RUN switch. To stop the motor, press the STOP switch. And so do in counterclockwise rotation, first step is press the CCW switch and then press the RUN switch. When we want to change direction while the motor is running, press the STOP switch, and then select the CW or CCW switch. Hardware Software Software flow chart Source code file in Full Step Mode ;**************************************************************** ;* Title : CW-CCW-RUN-STOP controls * ;* in Full Step Mode * ;* Author : Sony Sodikin * ;* Last updated: 04.03.14 * ;* Target : AT89C51/AT89S51 (AT89CXXXX/AT89SXXXX) * ;**************************************************************** org 0h start: jnb P2.0,start_cw ; cw option jnb p2.1,start_ccw ; ccw option sjmp start start_cw: jnb p2.2,step_cw ; run step cw sjmp start_cw start_ccw: jnb p2.2,step_ccw ; run step ccw sjmp start_cc...

.JPG)

.JPG)